Easy to buy

Variety mode of payment

Easy to buy

Variety mode of payment

Free shipping

For orders from 3,000,000 VND

Support 24/7

Even outside working hour

Contact Ho Chi Minh City

Tel: (028).3977.8269 / 0906.988.447

Email: sales@lidinco.com

Contact Bac Ninh, Ha Noi City

Tel: (0222).730.0180

Email: bn@lidinco.com

Saw control

Noise protection system Placid PSC

Overview

It employs Surface Acoustic Wave (SAW) technology to achieve accurate detection, analysis, and suppression of noise. The system is composed of a sensor array that is strategically positioned to pick up and record real-time noise levels within an area of interest. The recorded noise data is then processed by the system’s advanced signal processing algorithms and analyzed to identify the specific frequency ranges that require suppression.

Features & Benefits

The framework is as of now utilized for wear location on roundabout and band saws. It is sold in 15 countries around the world.

The amount of money saved by finding sawing defects ranges from 30% to 70%! The lines’ efficiency has increased by at least 30% as a result of precise monitoring.

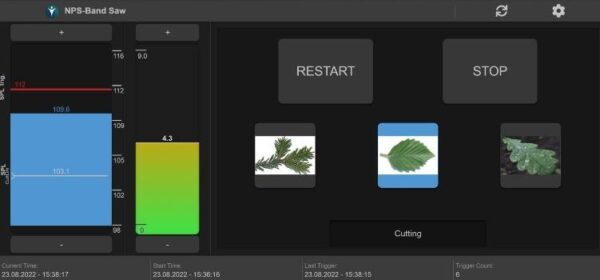

The user interface, which lets the operator choose between different operating programs and keep track of the sawing parameters that are currently being used.

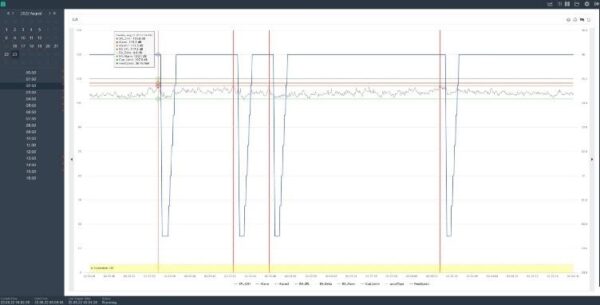

The current operating conditions can be seen in the graph on the left, and the blade’s wear can be seen in the right graph. The blade ought to be changed when the upper level is reached.

NPS system management is on the right side of the graphical user interface. We can start or stop the measurement and select from a variety of pre-set operating systems.

ALARM DISPLAY

Assuming an error during the cutting system occurred, the sound tension level (SPL) surpasses the caution esteem, and the framework becomes red to alarm the administrator. Additionally, the NPS system modifies the Relay Output (green connector), which is typically connected to the saw’s control system.