No products in the cart.

Easy to buy

Variety mode of payment

Easy to buy

Variety mode of payment

Free shipping

For orders from 3,000,000 VND

Support 24/7

Even outside working hour

Contact Ho Chi Minh City

Tel: (028).3977.8269 / 0906.988.447

Email: sales@lidinco.com

Contact Bac Ninh, Ha Noi City

Tel: (0222).730.0180

Email: bn@lidinco.com

High power and large volume hot air for quick removal of components:

FR-810B is the tool that can provide high power hot air and high volume airflow to rework on P.W.B. with high heat capacity.

Improving work efficiency:

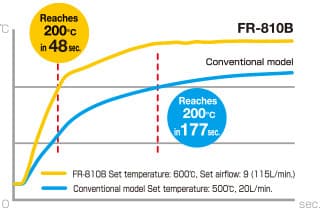

The high volume airflow and high output of FR-810B make it possible to perform the same work in only one-third of the time required when using a conventional model. This reduces the thermal impact on boards and components.

*The comparison of the time for the temperature of the solder joint of the component on the ceramic board to be heated to 200℃ under the maximum set temperature and maximum set airflow of the hot air stations.

*Single nozzles with an approximately 4mm diameter were used.

Improvements in FR-810B:

On top of the features of FR-810, high power and large air volume, the new functions of vacuum pickup and pickup indicator have been given to FR-810B.

The 2 new functions make it possible to remove a component without damaging PWB.

New type of nozzles for improvement of temperature characteristics:

The new nozzle improves work efficiency with uniform heating by hot air convection inside the nozzle which is created due to vents on the nozzle top. (Only with BGA nozzle)

The vacuum pickup function is to pick up a component with a suction pad and vacuum. It will pick a component only after the hot air melts solder joints. This can avoid an error to peel off the land by removing a component with excessive force.

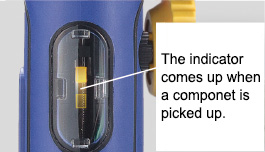

By pre-setting pickup function, a component can be picked up automatically when solder is melted. At the same time, the indication comes up and the moment of picking up will be visible. Even a component and solder joints can not be seen as covered by a nozzle, easy and safe picking up is possible.

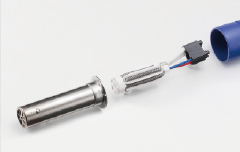

Simple nozzle removal and easy maintenance:

Nozzles can be quickly changed for many different types of components. In addition, conventional nozzles are compatible. Heaters can also be easily and securely replaced.

Timer function:

Timer function is to control the time of operation. This can help to prevent parts from overheating and can improve the overall quality of rework.

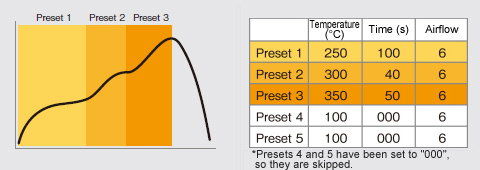

Chain presets function for making a simple thermal profile:

The chain presets function is to make a simple thermal profile by combining several preset conditions. (Up to 5 steps) This can improve work efficiency a lot by standardizing work time, avoiding overheating, improving repeatability of operation, and making difficult rework jobs easy.

Auto sleep and auto shutoff functions:

To ensure safety and conserve power, when the handpiece is placed in the handpiece holder, the auto sleep function will be activated and it will start cooling automatically. If the handpiece has not been removed from the handpiece holder (e.g. Using it in a rework fixture) and it has been idle for 30 minutes, auto shutoff function will be activated. It will be automatically powered off. Access to settings can be restricted by the password function.

Model: FR-810B

Power consumption:

AC100V:700W

AC110V:840W

AC120V:820W

AC220V:1,100W

AC230V:1,200W

AC240V:1,300W

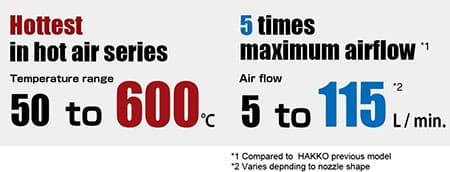

Temperature range: 50 to 600℃

Power consumption: 30W

Air flow: 1-9(5 to 115L/min)L/min.

Dimensions: 160(W)×145(H)×220(D)mm

Weight: 1.5kg

.Handpiece (Hot air)

Power consumption:

AC100V:670W

AC110V:810W

AC120V:790W

AC220V:1,070W

AC230V:1,170W

AC240V:1,270W

Standard nozzle: 4mm dia. (N51-02)

Total length: 250mm

Weight: 180g

*Total length and weight for handpiece are measured without cord and standard nozzle.

*Airflow capacity is rated as free flowing. Restrictions created by various nozzles may reduce the maximum airflow capacity.