No products in the cart.

Easy to buy

Variety mode of payment

Easy to buy

Variety mode of payment

Free shipping

For orders from 3,000,000 VND

Support 24/7

Even outside working hour

Contact Ho Chi Minh City

Tel: (028).3977.8269 / 0906.988.447

Email: sales@lidinco.com

Contact Bac Ninh, Ha Noi City

Tel: (0222).730.0180

Email: bn@lidinco.com

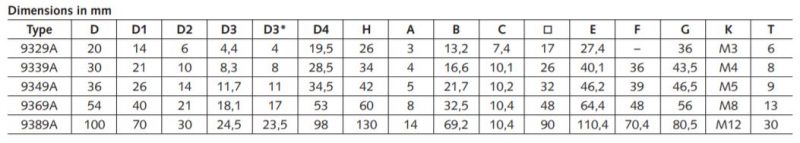

These easy to install piezoelectric reaction torque sensors are particularly suitable for measuring rapidly changing torques at non-rotating shafts. Five different size sensors are available for the measuring ranges ±1 N·m, ±10 N·m, ±25 N·m, ±200 N·m and ±1 000 N·m.

• Two calibrated measuring ranges: 100 %, 10 %

• Very compact, ready to install reaction torque sensor

• Flexible adaption with mounting threads in double flange

• Centering seats for coaxial mounting and optimum introduction of torque

• Centric bore for shaft passage

• Can be used as torque calibration sensor

The reaction torque sensor is integrated under high preload between preload screw and nut. When a torque acts on a sensor, the shear stresses produced are transmitted to the crystals. The charge signal proportional to the force is picked up by an electrode and fed through a screened cable to a charge amplifier. The charge signal is converted by the charge amplifier to a proportional output voltage, which can be recorded and evaluated.

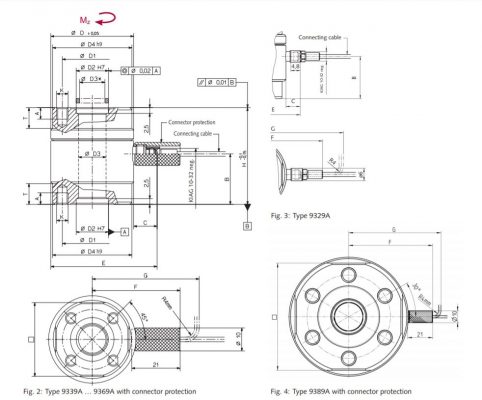

Flanges on the top and bottom sides of the reaction torque sensor allow simple and direct installation on a shaft or adapter flange. This allows very low, space-saving installation. Alternatively, a mounting flange (optional accessories) can be used or installation can take place using custom adapters. A two-sided centering facility allows very accurate coaxial fitting. A centric bore allows additional applications, e.g. for shaft bushing. A screw-on connector cover ferrule is provided with the included accessories to protect the cable connection at the side. Kistler reaction torque sensors reliably detect even the slightest torques acting on the sensor axis in both rotary directions.

The sensor is suitable for measuring a dynamic or quasistatic torque acting on the sensor axis.

Examples of Application

• Torque setting of pneumatic screwdrivers

• Testing screw connections

• Calibration of manual torque wrenches

• Torque testing of springs

• Measurements on friction clutches

• Measurement of starting torques on electric motors

• Measurement of irregular rotation and torsional vibrations on small servo and stepper motors

• Testing of rotary switches (product testing)