No products in the cart.

Easy to buy

Variety mode of payment

Easy to buy

Variety mode of payment

Free shipping

For orders from 3,000,000 VND

Support 24/7

Even outside working hour

Contact Ho Chi Minh City

Tel: (028).3977.8269 / 0906.988.447

Email: sales@lidinco.com

Contact Bac Ninh, Ha Noi City

Tel: (0222).730.0180

Email: bn@lidinco.com

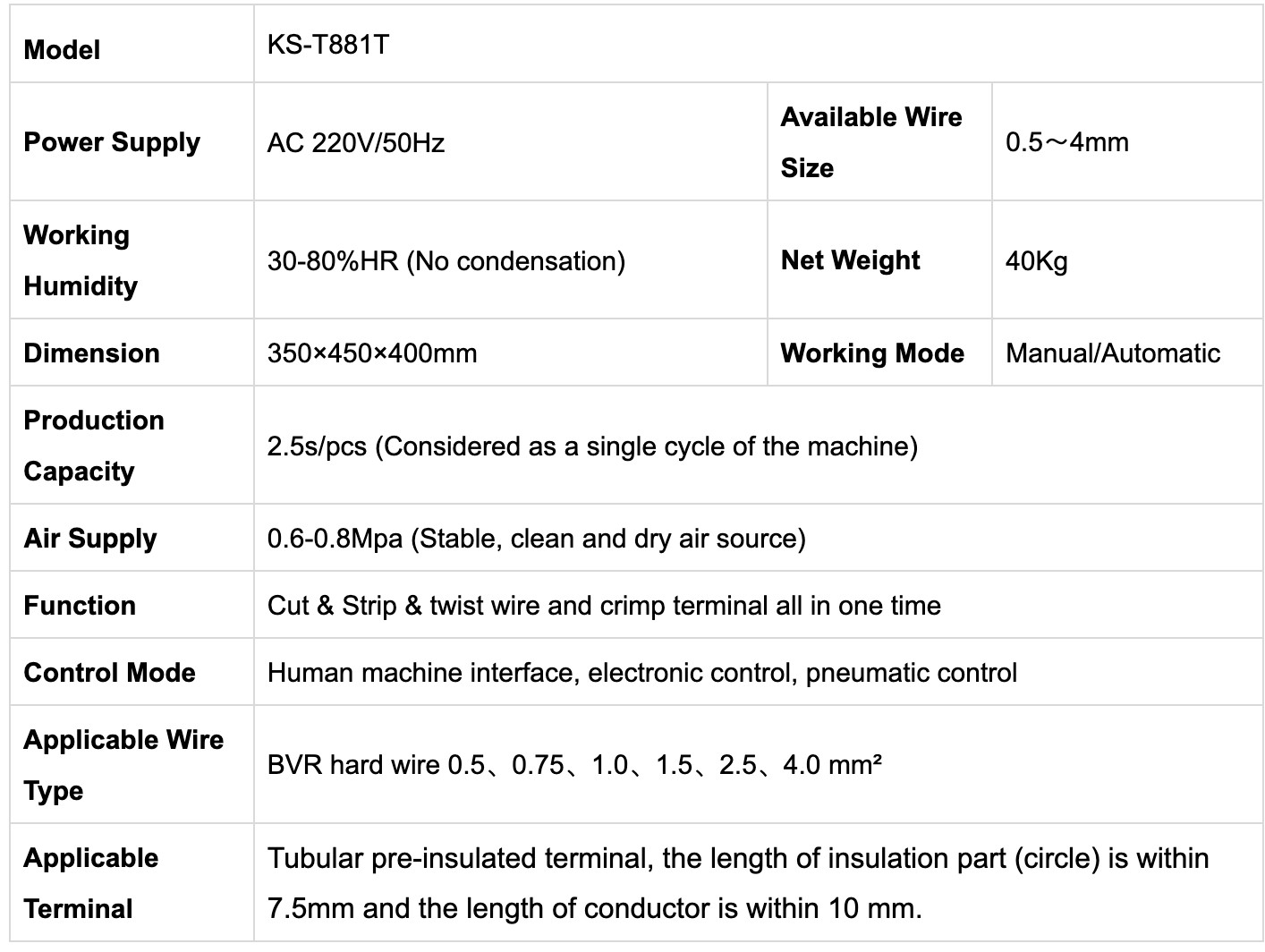

Automatic Wire Stripping and Ferrules Crimping Machine KS-T881T provides efficient processing of loose wire end sleeves/ferrules with plastic collars in different lengths. The ferrules are automatically fed by vibration plate, stripping and crimping in one work step which greatly improves the crimping efficiency of the ferrules. The feeding guide rail is easy to adjust. One machine can be used for terminals of different sizes.

Easy to program and operate;

Excellent price/performance ratio;

With sensitive pneumatic induction control, crimping quickly;

Feeding of vibration plate, wire stripping, terminal wearing and crimping in one work step;

High level of reliability due to maintenance and wear-free components;

No special tooling for stripping length adjustment required. Robust & reliable, High working efficacy; Inductive switch, safer and more convenient;

Place wire with bell mouth, fully sealed shape design, safe operation, reduce the possibility of injury, and ensure a more beautiful appearance under the premise of safety;

Operation with touch screen, electric adjustment, save the set parameters and can be directly called;

Automatic feeding, labor-saving and time-saving, and simple adjustment is needed for changing specifications, which is convenient and quick;

Different crimping specifications, there is no need to replace the crimping applicato.